Since the beginning of this project, almost everyone we have spoken to has asked, “Will you be eating it?” and “But how does it taste?” While we are curious as well…1) no one wanted to volunteer to try the food, and 2) schools have something called an institutional review board (IRB), a research ethics committee, that would prevent us from endangering anyone with the food even for the sake of science. Thankfully, we found out not long ago that Texas A&M University has an excellent Animal Science department that specializes in meat science, and there are ways to quantify flavors using a method called Gas Chromatography-Mass Spectrometry! Helen Chen, our research assistant, recounts our field trip to Dr. Chris Kerth’s laboratory.

Gas Chromatography-Mass Spectrometry Field Trip

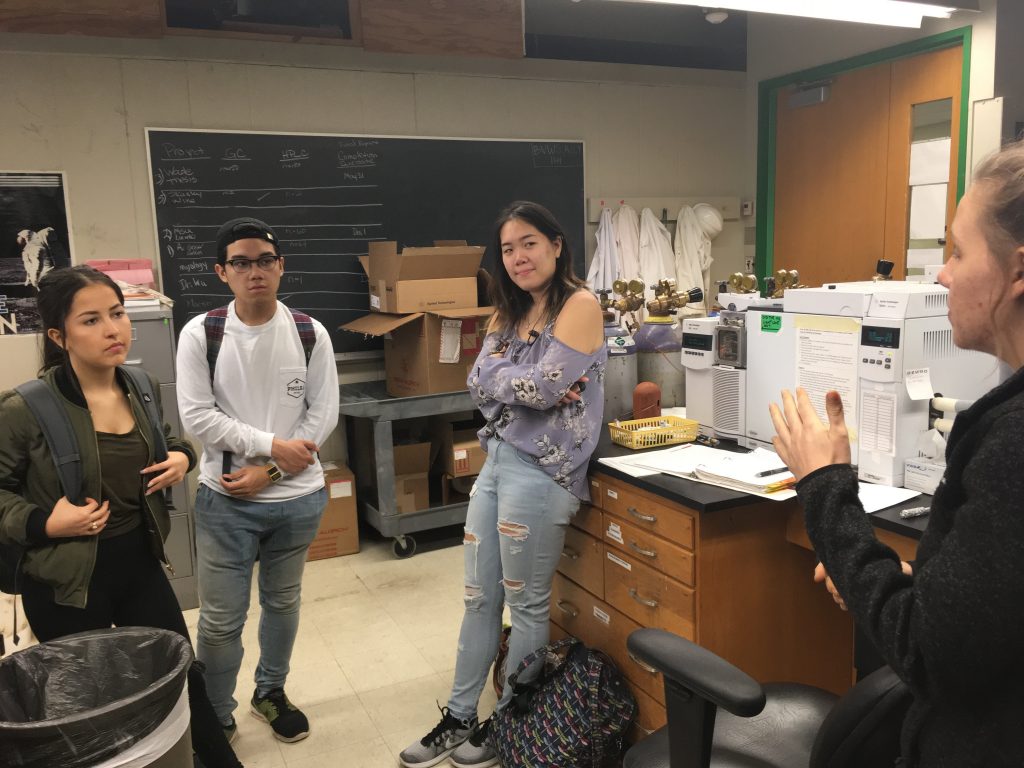

ARS students (L to R: Daniela Trevino, Christian Encarnacion, Helen Chen) learning about GCMS with PhD student lab tech, Kayley Wall (Right).

By Helen Chen

Have you ever wondered what food smelled and tasted like for 17th-century sailors? Well, today we decided to find out by taking a field trip and speaking with Kayley Wall, a PhD graduate technician in Dr. Kerth’s laboratory. Her research involves her expertise in smelling various compounds through the use of a Gas Chromatography-Mass Spectrometry or GC/MS. GC/MS works by converting compounds such as coffee beans into a volatile or gas-like vapor through the use of heat.

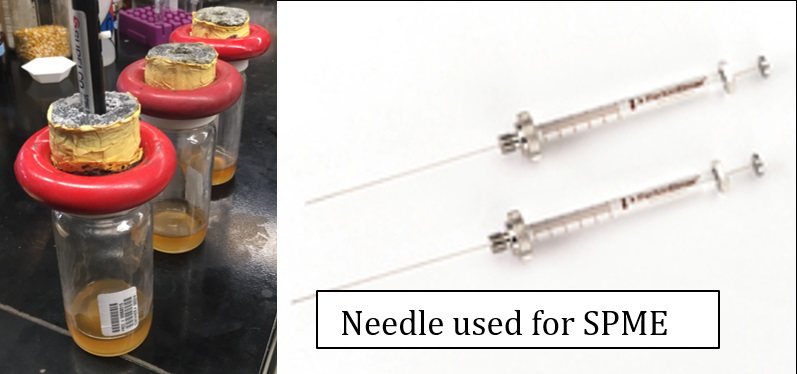

The first step in the GC/MS is to put a small needle into a container with our compound for a couple of hours. The stainless needle fibers will absorb the various

A few food samples in jars, one shown with the needle inserted that absorbs the volatile compounds (SPME).

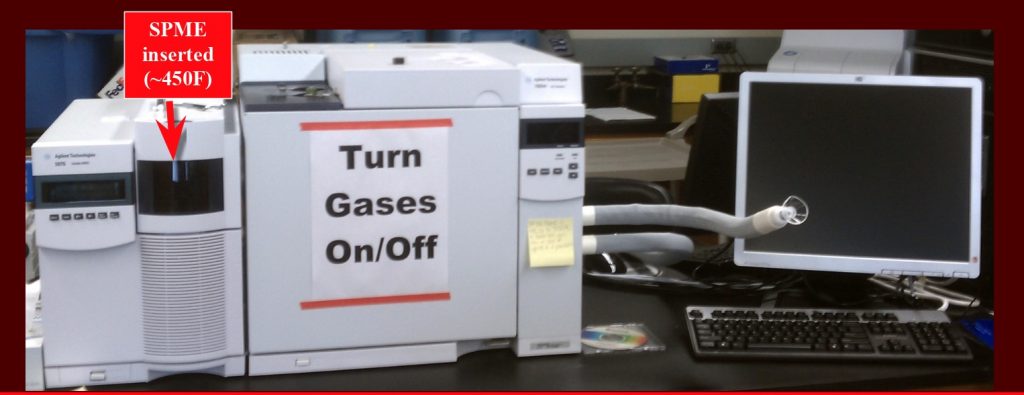

chemical compounds from the sample. This process is called solid phase micro-extraction or SPME for short. Then, we remove the needle and place it into our machine that acts like an oven. This machine quickly increases the temperature from 100°F to 450°F in 30 minutes. This massive temperature increase will break down the different chemicals and vaporize them at various times. We are able to separate compounds based on volatility (ability to become a vapor/gas), charge and size. The separation of compounds is due to hydrolyzing fatty acids and proteins and breaking them down into volatile compounds. The peaks on the graph are based off of how many chemical compounds are given off, so you can see the amount of mass those chemical compounds were in comparison to all the other compounds. Usually in the GC/MS, there are Trimethylsilylation derivatives for quality control analysis because we already know how that peak is supposed to look on the graph.

The GCMS Machine.

Additionally, using the sniffer port, we are able to note how people would perceive the smells of the different chemicals. There are some chemicals that do not register strongly in humans’ olfactory systems and others that do. Different quantities of different types of volatile chemicals can thus be qualified using their flavor such as buttery, or sweet, and rated on their intensity level on a 1-14 scale, by a trained technician.

Using GC/MS, we can quantify the various flavor profiles for our salted beef, cod, and more from our Salted Beef and Salted Biscuit Project. Further analyses can be done with High-Performance Liquid Chromatography (HPLC), which allows us to separate and quantify the non-volatile components based on how long they take to separate from a long column.